In the jewelry-making industry, the precision and quality of the final product rely heavily on the casting mold process. Cristobalite – a high-temperature-resistant crystalline form of silica – has become a rising star in jewelry casting for its ability to create ultra-smooth, durable molds that can withstand extreme heat. With the continuous growth of the global jewelry market, incorporating Cristobalite not only elevates product quality but also helps businesses optimize costs and maintain a competitive edge internationally. In this article, Phenikaa Hue reveals the vital role of Cristobalite in jewelry casting and why it is an essential solution for modern jewelers.

1. Cristobalite and the jewelry casting industry

Cristobalite is a mineral form of silicon dioxide (SiO₂), similar to quartz but with a unique crystal structure formed at high temperatures (above 1,470°C). With a hardness of 6.5–7 on the Mohs scale, exceptional heat resistance (up to 1,710°C), and high chemical stability, Cristobalite is widely used in investment casting techniques.

The global jewelry industry is currently booming, with a market value reaching hundreds of billions of USD and expected to continue its rapid growth in the coming decade, driven by rising incomes, shifting consumer preferences, growing demand for personalized jewelry, and an increasing focus on sustainability.

Jewelry casting, though rooted in ancient traditions, remains a core process in modern jewelry-making. This involves creating a wax model, surrounding it with a heat-resistant mold material (such as Cristobalite), heating to remove the wax, and finally pouring molten metal into the mold to produce intricate, high-quality jewelry pieces.

2. Standards for cristobalite powder used in jewelry casting

Composition and purity

Cristobalite powder for investment casting requires a minimum SiO₂ content of 99.5%, ensuring exceptional purity for the final product.

The raw material is typically sourced from high-quality quartz ore, carefully selected and subjected to heat treatment at around 1,500°C to transform its crystal structure. It is then finely milled and sieved to strictly controlled particle sizes, commonly in the 600–800 mesh range for Cristobalite powder.

Cristobalite’s tetragonal crystal structure provides outstanding thermal stability and refractoriness—key factors in high-temperature casting applications, particularly in the creation of fine jewelry.

Particle size and physical properties

The particle size of Cristobalite powder is tightly controlled to ensure uniformity, optimizing mold-making performance. Its near-spherical grain shape and consistent size distribution help produce smooth mold surfaces, resulting in highly finished cast products.

Cristobalite powder exhibits a hardness of about 6.5–7 on the Mohs scale, a density of approximately 2.45, a large specific surface area, high porosity, and excellent thermal shock resistance.

These properties enable the material to withstand extreme temperatures and rapid thermal changes, making it ideal for the demanding requirements of casting precious metals such as gold, platinum, and silver.

3. Typical formula of investment casting powder in jewelry manufacturing

Investment casting powders used in jewelry manufacturing — including those containing cristobalite — are typically formulated with either a gypsum-based or silica-based binder system.

A common composition for precision investment casting powder includes:

- 25–35% alpha hemihydrate gypsum (α-hemihydrate)

- 65–75% silica powder

Additionally, superplasticizers and antifoaming agents are incorporated to fine-tune slurry flowability, smoothness, and rheological properties.

For premium-grade powders specifically designed for high-quality gold alloys (up to 24K), the formulation often includes specially refined cristobalite and optimally engineered refractory minerals. This combination enables precise control of thermal expansion while producing exceptionally smooth mold surfaces and sharp casting details.

4. Role and key characteristics of cristobalite in jewelry casting molds

Thermal expansion control

Cristobalite features a stable tetragonal crystal phase that undergoes distinct phase transitions around 250 °C and 570 °C, accompanied by positive volumetric expansion. This property compensates for the natural shrinkage of gypsum molds during firing, maintaining structural integrity and minimizing cracking or deformation.

As a result, cast pieces retain sharp details and smooth surfaces. In many formulations, cristobalite increases the overall thermal expansion of the mold by over 1%, making it ideal for withstanding thermal stresses when casting gold, silver, and platinum.

Enhancing mold strength

When combined with gypsum-based binders, cristobalite increases compressive strength through controlled expansion during setting and heating. This prevents mold cracking, metal leakage, or breakage, ensuring the preservation of intricate details — a critical factor in high-end jewelry making.

Optimized particle size & permeability

Finely milled cristobalite with tightly controlled particle size distribution improves mold gas permeability. This allows trapped gases to escape efficiently during metal pouring, minimizing porosity and defects while delivering cleaner, brighter, and more uniform surfaces.

Outstanding thermal shock resistance

With high hardness and excellent thermal shock resistance, cristobalite enables molds to withstand sudden temperature changes during burnout and pouring. This is essential for protecting delicate patterns and preventing deformation or mold collapse.

Superior surface finish

Cristobalite’s natural white color and fine particle size contribute to smooth mold surfaces, resulting in highly finished castings and significantly reducing post-casting polishing work.

5. Factors affecting mold quality when using cristobalite

Cristobalite purity

This is the most critical factor, directly impacting the mold’s heat resistance, as well as its chemical and physical stability. High-purity cristobalite (SiO₂ > 99.5%) ensures precise thermal expansion control, enhances mold strength, and minimizes unwanted reactions with molten metals.

Cristobalite particle size

Typically controlled within the 600–800 mesh range, particle size determines mold smoothness, effective gas permeability, and good mechanical strength. Oversized or undersized particles can negatively affect mold durability and the surface quality of the final casting.

Cristobalite mixing ratio in investment powder

An optimal proportion (typically 2–10%) strikes a balance between thermal expansion and mold hardness, preventing cracks or breakage while ensuring sharp, detailed mold reproduction.

Firing Temperature and Soaking Time Related to Cristobalite

Proper firing temperature and holding time complete the phase transformation of cristobalite, enhancing mold strength and stability. Incorrect firing conditions can cause uneven crystal structure transformation, leading to brittle or cracked molds.

Alkali Impurity Content (Especially Na⁺) in Cristobalite

For jewelry casting applications, the allowable Na⁺ content in cristobalite powder is typically very low — usually under 0.2–0.22 wt% Na₂O (including sodium ions Na⁺). This strict limit ensures predictable thermal expansion, mold durability, chemical inertness, and high casting quality without sodium-related defects.

Uniform Distribution of Cristobalite in the Mixture (Mixing Process)

Thorough mixing and agitation ensure even distribution of cristobalite, preventing agglomeration, maintaining consistent mold properties, accurately reproducing fine details, and reducing casting defects.

6. Cristobalite của Phenikaa Huế

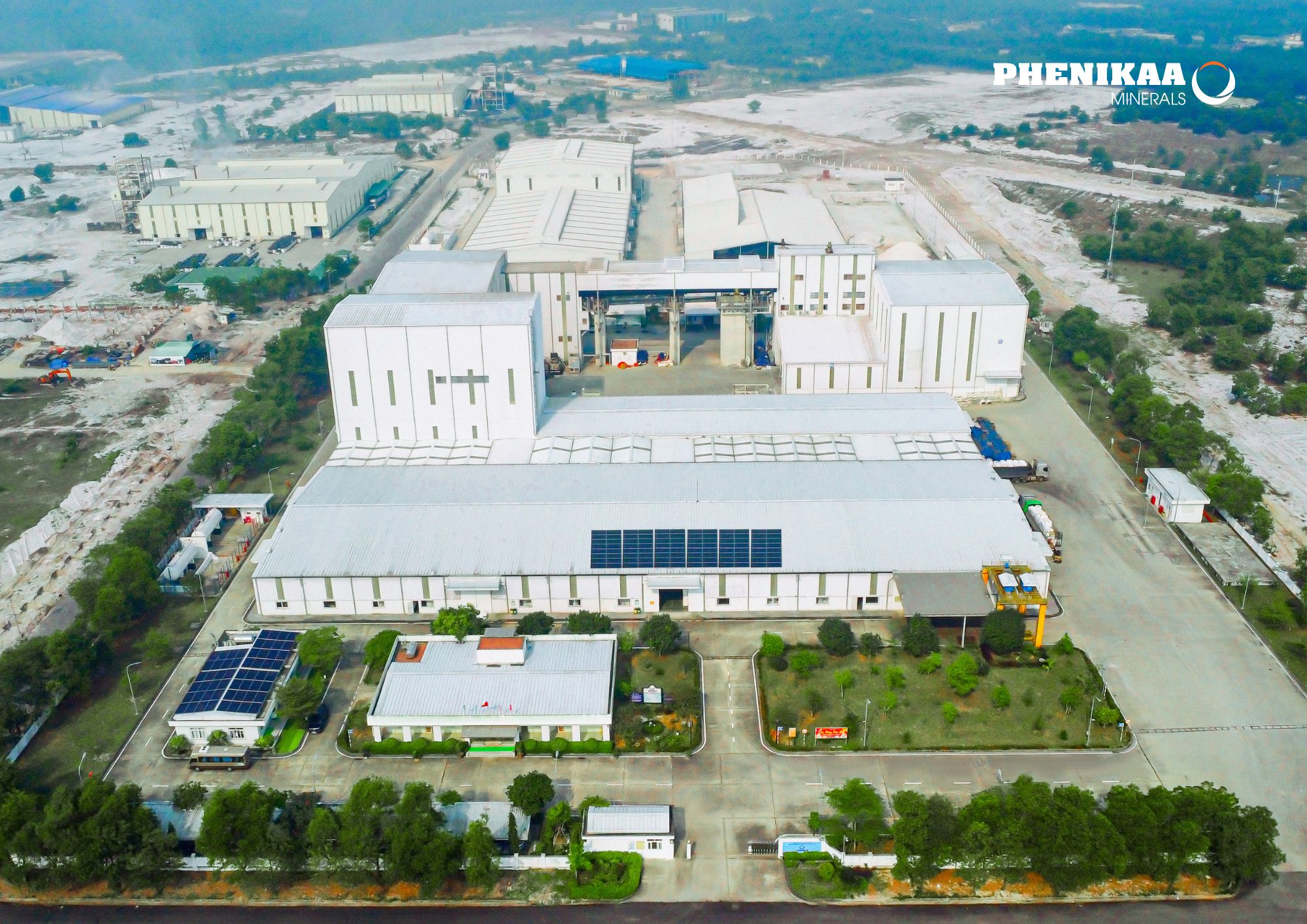

Phenikaa Huế’s Cristobalite is manufactured with exceptional purity, fine particle size, and superior technical properties, fully meeting the most stringent standards of the global jewelry investment casting industry. The product delivers outstanding heat resistance, precise thermal expansion control, and smooth, sharp mold surfaces — key factors in producing intricate jewelry details, from 24K gold alloys to other precious metals.

With advanced production capabilities, internationally certified quality management processes, and a team of experienced experts, Phenikaa Huế not only supplies high-quality materials but also partners with customers by providing information support, technical consulting, and a range of value-added services to optimize production efficiency and enhance final product quality.

>>> View the full technical specifications and chemical composition of Phenikaa Hue Cristobalite

Contact us today to experience the quality of our Cristobalite and receive expert consultation:

📞 Hotline: +84 79 660 8686

📧 Email: kdvt.pnkh@phenikaa.com

🌐 Website: www.phenikaahue.com

📱 Facebook: @Phenikaahue

💼 LinkedIn: Phenikaa Hue